Fabrication of well-ordered array of isolated epitaxial BiFeO3/CoFe2O4/SrRuO3 heterostructured nanodots

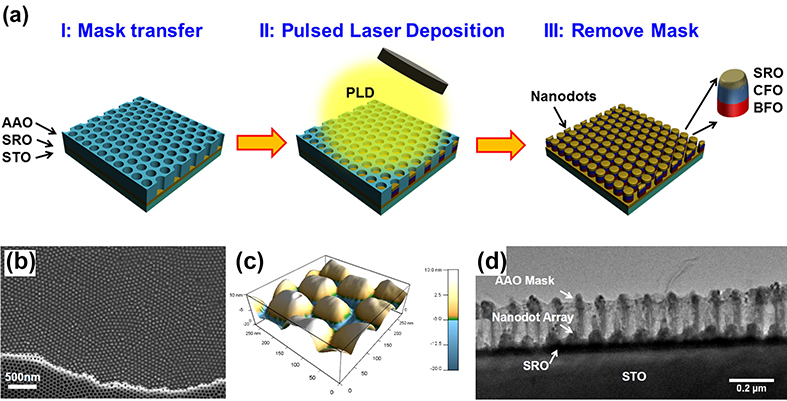

Multiferroic magnetoelectric (ME) composites exhibit sizable ME coupling at room temperature, promising applications in a wide range of novel devices. In 2016, Xiaoyan Zhang et al. explored the well-ordered array of isolated epitaxial BiFeO3/CoFe2O4/SrRuO3 heterostructured nanodots fabricated by nanoporous anodic alumina (AAO) template method. A schematic of the fabrication process is illustrated in Fig. 1a, which involves three steps: AAO mask transfer (i), materials deposition by PLD (ii), and mask removal (iii). The AAO mask was removed by mechanical or chemical liftoff, thus leaving the nanodot array alone. The thickness of AAO film is about 250 nm. The nanodots exhibit an average lateral size of ¡«70 nm and neighboring dot−dot distance of ¡«110 nm. It was found that the heterostructured nanodots yield apparent ME coupling, likely due to the effective transfer of interface couplings along with the substantial release of substrate clamping. These results offer good opportunities of the nanodots for applications in high-density ME devices, e.g., high density recording (>100 Gbit/in.2) or logic devices.

Fig. 1 Fabrication process and microstructures for the BiFeO3/CoFe2O4/SrRuO3 nanodot array. (a) A schematic flowchart for the fabrication procedure. (b) A top-view SEM image of the nanodot array. (c) The ¦È-2¦È XRD diffraction pattern and (d) a reciprocal space mapping (RSM) adjacent to the STO (002) plane.

Reference:

ACS Nano 2016, 10, 1025−1032.

http://pubs.acs.org/doi/abs/10.1021/acsnano.5b06339