The ideal filter membrane should have uniform pore size, which can achieve precise control of the key processes, such as filtration, separation, purification and material preparation, so that it can be widely applied in the fields of high fine chemical industry, medical treatment, biopharmaceuticals, quality detection and water treatment. However, the existing membrane preparation technology, such as the processing method to track etched on behalf of and for the phase transformation and interfacial polymerization method for chemical synthesis technology, has disadvantages of complex technology, complex process, difficult to control, and can not achieve precise control of the pore size of the membrane, which directly affects the existing in the application inefficient or even invalid.

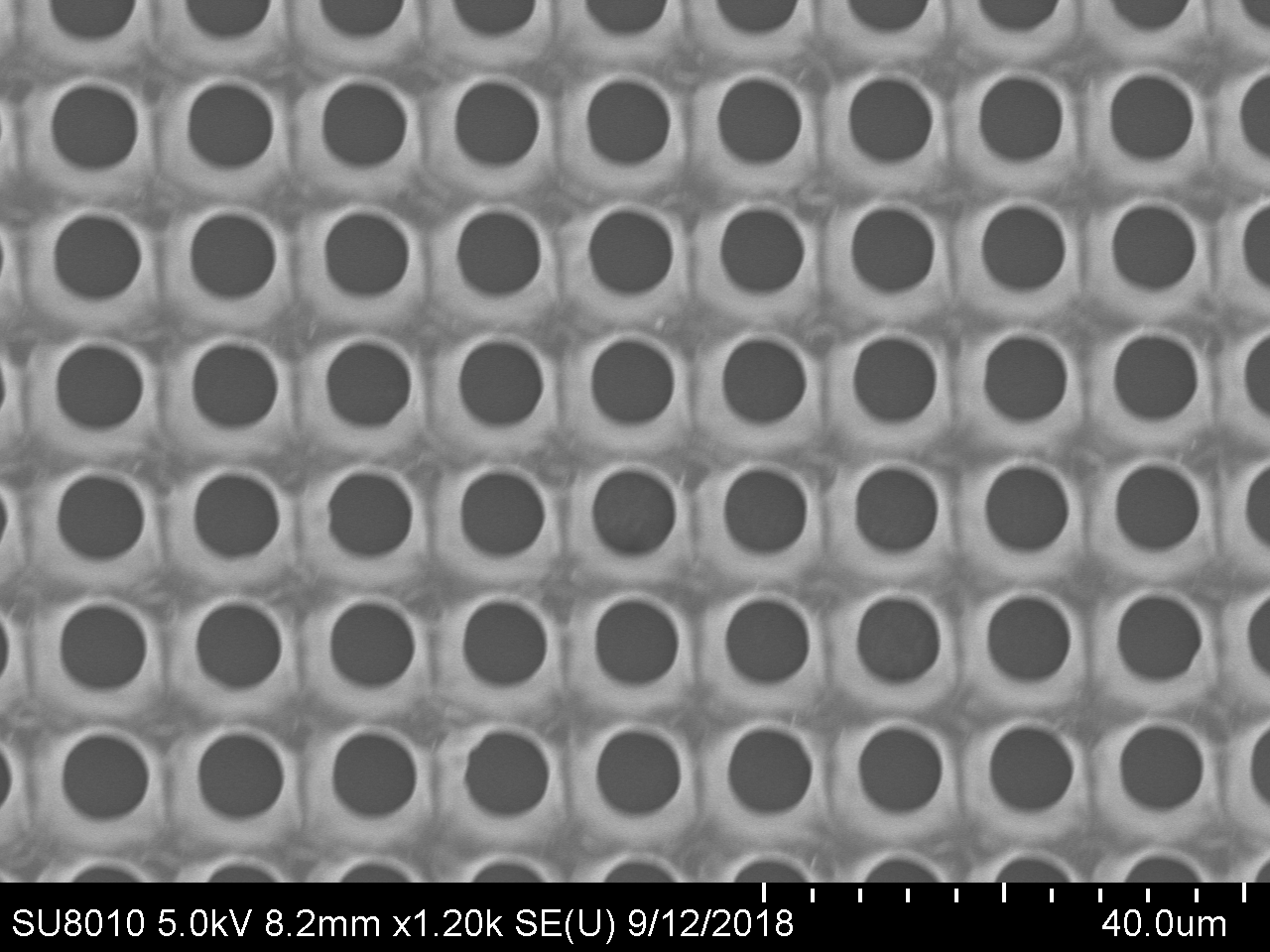

The design of our membrane technology has achieved the controllable processing of the membrane. Based on the characteristics of micro and nano technology, the advanced microfiltration process developed by us is a very original micro nano processing technology, which truly realizes the precise control of the size, distribution and porosity of the filter membrane. The membrane materials of this technology to produce the aperture coefficient of standard deviation is less than 0.1% (excellent foreign brand aperture in general 15%-20% standard deviation), high porosity (effective porosity of up to 80%), and the vertical hole wall is smooth, can greatly improve the filtration efficiency, reduce maintenance cost. This innovative high - end filter membrane preparation technology is simple (only once), easy to produce in large scale, and is more green. Not only can substantially increase the efficiency in high fine chemical, medical, pharmaceutical, food, beverage, environmental monitoring and water treatment in the field of filtration, separation, purification and preparation of materials, and the various parameters and process control of these processes is more precise and predictable. It plays an important role in the preparation of nanomaterials. Compared with other membrane products at home and abroad, many key indicators of this product, such as pore size uniformity, porosity, through-hole rate, water flux, rejection rate, chemical physical stability, mechanical strength and so on, surpassed similar products.

At present, the membrane technology based on modified micro and nano processing is mainly used for the development and application of customized products and technologies. Its applications include flexible electronic technology, ultracapacitor and other applications based on organic materials.